Each test specimen undergoes a series Of procedures before you received it. Our unique quality assurance secures the Effectiveness of your test series:

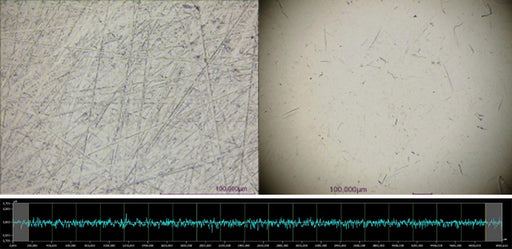

By optical inspection, we eliminate scratches, rust and other macroscopic damages on the specimen surfaces.

By intensive, semi-automated roughness measurement and evaluations, we assure that the roughness parameters of every batch remain within the specified parameters.

Surface microscopy of a OPD (left) and surface microscopy of a OPB (right)

For every batch that leaves Optimol, we verify the hardness of the specimen to assure the consistency with the standard specifications.

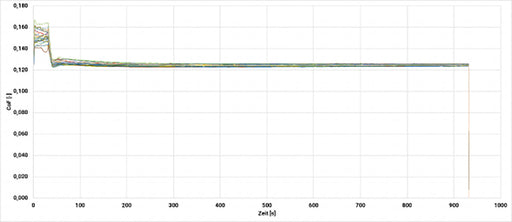

On random samples taken from every OPD batch, we carefully check the stability and consistency of the coefficient

of friction and resulting wear scar with our reference oil in order to maintain reproducibility.

As our OPD are also reference samples for extreme pressure tests, we verify the pass load of several random samples out of every batch.

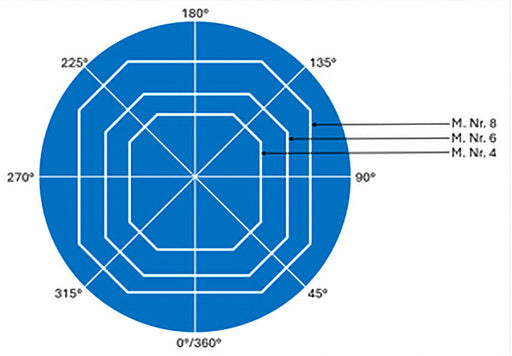

We regularly screen the CoF values on different positions on the disk surfaces with special test procedures to ensure the homogeneity of the results on each position of the disk.

Thanks to our new stable and reliable production process as well as our intensive quality assurance procedure, the repeatability of the results is extremely precise.

Diagram of more than 30 quality assurance tests of our OPD as proof of a constant repeatability of 95 %

We guarantee the traceability of every batch through our Optimol quality assurance database. Each batch is registered and gets an explicit batch number allowing us to trace the history of every single OPS batch.

With every pack of OPS an individual certificate is provided, including most important specifications like hardness and roughness values, CoF for the reference run andv alidity.